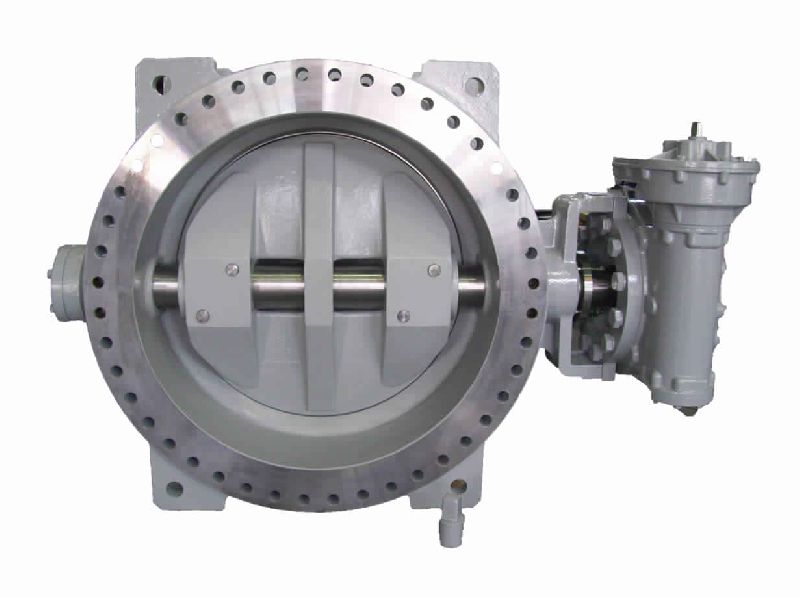

Description

Features And Benefits

- Replaceable cartridge seat design with solid backup ring allows best fit for vacuum applications and minimum costs over lifetime.

- Only 2 wetted parts, disc and seat, with no exposed metal-to-metal contact points, for maximum corrosion resistance.

- Self-centering disc with smooth finish and spherical edge reduces wear and resists corrosion and abrasion.

Technical Details

DESIGN FEATURES

- Usable as quick closing valve

- Concentric design

- Soft seat design

- No pins connection between disc to the shaft, only 2 parts in contact with the medium

- Replaceable body lining with firm back-up ring

- Permanently tight closure

- Optimum operation under vacuum conditions

- Standardized top flange for actuator adaption

- Materials for almost all media

- Short face-to-face dimension

- Maintenance-free version

- Blow-out proof shaft

- Direct mounting of actuators without any additional brackets

SIZE RANGE

- DN 40 up to DN 1400, 1 1/2” up to 56”

PRESSURE RATINGS

- PN10, PN16, ASME class 150

TEMPERATURE RANGE

- -30°C (-22°F) up to 200°C (392°F) depending on material selection

BODY CONFIGURATION

- Lug type

- Wafer type

- Wafer type with centering lugs

- Double flanged

SPECIAL OPTIONS

- Additional trunion bearing for high cycling applications

- Shaft extensions

Applications

- Paper industry

- Sugar industry

- Power generation plants

- Chemical and petrochemical industry

- Steel industry

- Automotive industry

- Energy supply

- Shipbuilding industry

- Breweries

- Cement plants

- Cleaning Units

Reviews

There are no reviews yet.